WHS for Health and Safety Committees – NSW Edition

Lesson 4 – Topic 2: Examples of Risk Management Systems

Examples of Risk Management Systems

Scheduled Safety Inspections

Scheduled safety inspections of plant and work environment usually using checklists. These inspections are typically carried out by Health and Safety Committee members as well as Health and Safety Representatives. These inspections must allow for consultation to occur with relevant workers during the inspections. Safety inspections are not complete until the results have been discussed and handed over to management for corrective actions.

Change Management

A process that allows staff with different areas of expertise to analyze and comment on the potential consequences of any change to procedure, process, plant, or environment, before the change is made.

Project Safety Review

A documented system that manages risk after a project has been completed but before the project is put to day to day use or operation.

Hazard Reporting (ad hoc)

A system that allows any worker to formally raise safety concerns at any time. It should also allow a worker to make recommendations for corrective action.

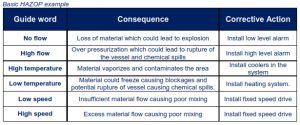

HAZOP (Hazard and Operability Study)

A hazard identification technique that is based on “guide words” that provoke thoughts about how deviations from normal or intended operating conditions can lead to hazardous situations. It is typically used, but not limited to, in the chemical, oil & gas, power generation mining and metals and pharmaceutical industries.

Lockout / tag out

The placement of lockout devices (e.g. padlocks) on energy control devices such as isolators, valves so that each worker is in exclusive control of all energies feeding the equipment they are working on. This ensures that the equipment can not be energized until the last worker has removed his or her lockout device.

Tags are usually used in conjunction with the locks as additional information and warning.

Occupational Health and Safety Management System (OHSMS) Audits

A health and safety audit is an independent, systematic and periodic review of the Occupational Health and Safety Management System (OHSMS) which includes policies, procedures and programs. The audit measures performance of the OHSMS against a pre-defined standard. A widely used standard in Australia is AS/NZS 4801 Occupational Health and Safety Management Systems.

Auditors will evaluate an organization’s OHSMS against requirements within each of the following 5 areas as described in AS/NZS 4801:

- 1) OHS Policy

- 2) Planning

- 3) Implementation

- 4) Measurement and evaluation

- 6) Management review

When the audit is completed, a report will be issued including any non-conformances for which corrective actions will be requested.

There are many reasons why organizations implement an OHSMS including legal, ethical and also to improve financial performance. But of course the prime reason for implementing an OHSMS is to reduce workplace injury and illness.

Some auditing organizations offer certification audits of the OHSMS. These organizations must be accredited by the Joint Accreditation System of Australia and New Zealand (JAS-ANZ)

However, OHSMS certification or positive audit results, do not necessarily mean that an organization has met its legal WHS obligations.